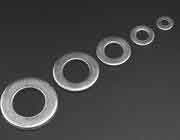

Inconel 725 flat washers are strong and corrosion resistant making them well suited for seawater applications.

In fact, Inconel 725 flat washers are twice the strength of Inconel 625 thanks to its heat treatment. Made with nickel, chromium, molybdenum, and niobium, Inconel 725 is an age-hardenable alloy that has essentially the same corrosion resistance as Inconel 625. Importantly, Inconel 725 is resistant to hydrogen embrittlement and stress-corrosion cracking as well as being incredibly tough.

Inconel 725 Characteristics

- Resistant to stress-corrosion cracking

- Resistant to sea water

- Excellent fracture toughness

Applications

- Petrochemical

- Processing

- Marine

- Aircraft

- Hangars

- Landing nipples

- Springs

- High-strength marine applications

- Sour gas service

- Chemical processing

- Aerospace

- Oil and gas industries

We offer washers to the specific dimensions that you need. Special sizes can be made to order. We offer off-the-shelf sizing ranging from 0.062 to 12 inch inside diameter and thicknesses from 0.002 to 1/2 inch.

Standard line:

- USS

- SAE

- Fender washers

- Special sizes can be manufactured

Metric line:

- Din 125 A/B flat washers

- Din 433 small series flat washers

- Din 9021 fender washers

- Special sizes can be manufactured

Whatever Inconel 725 flat washer you’re looking for, if we don’t have it on our shelf, we can quickly get it to you. Our washer manufacturing capabilities range from small (under 100 pieces) to large runs. We will custom make your Inconel 725 flat washers to your exact specifications. Contact us today by email to inquiry.custom@shapedparts.com or filling out our contact form.

Anchor Bolts

Anchor Bolts

Carriage Bolts

Carriage Bolts

Elevator Bolts

Elevator Bolts

Eye Bolts

Eye Bolts

Hanger Bolts

Hanger Bolts

Heavy Hex Bolts

Heavy Hex Bolts

Hex Bolts

Hex Bolts

Hook Bolts

Hook Bolts

J Bolts

J Bolts

Lag Bolts

Lag Bolts

Plow Bolts

Plow Bolts

Rod End Bolts

Rod End Bolts

Stadium Seat Bolts

Stadium Seat Bolts

Tap Bolts

Tap Bolts

U Bolts

U Bolts

Cap Nuts

Cap Nuts

Coupling Nuts

Coupling Nuts

Flange-Serrated Nuts

Flange-Serrated Nuts

Hex Machine Screw Nuts

Hex Machine Screw Nuts

Hex Nuts

Hex Nuts

Hex Slotted Nuts

Hex Slotted Nuts

Metal & Nylon Lock Nuts

Metal & Nylon Lock Nuts

Non-Serrated Flange Nuts

Non-Serrated Flange Nuts

Thumb Nuts

Thumb Nuts

Weld Nuts

Weld Nuts

Wing Nuts

Wing Nuts

Blind Rivets

Blind Rivets

Countersunk Rivets

Countersunk Rivets

Semi-Tubular Rivets

Semi-Tubular Rivets

Solid Rivets

Solid Rivets

Structural Rivets

Structural Rivets

Button Socket Cap Screws

Button Socket Cap Screws

Concrete Screws

Concrete Screws

Deck Screws

Deck Screws

Hex Cap Screws

Hex Cap Screws

Machine Screws

Machine Screws

Self-Drilling Screws

Self-Drilling Screws

Self-Tapping Screws

Self-Tapping Screws

Sems Screws

Sems Screws

Set Screws

Set Screws

Shoulder Socket Screws

Shoulder Socket Screws

Socket Cap Screws

Socket Cap Screws

Tapping Screws

Tapping Screws

Thread Cutting Screws

Thread Cutting Screws

Thread Forming Screws

Thread Forming Screws

Thumb Screws

Thumb Screws

Weld Screws

Weld Screws

Wood Screws

Wood Screws

Beveled Washers

Beveled Washers

Flange Washers

Flange Washers

Flat Washers

Flat Washers

Hardened Washers

Hardened Washers

Plastic Washers

Plastic Washers

Shoulder Washers

Shoulder Washers

Lock Washers

Lock Washers

Special Washers

Special Washers

Spring Washers

Spring Washers

Wave Washers

Wave Washers

Dowel Pins

Dowel Pins

Spring Pins/Roll Pins

Spring Pins/Roll Pins